Tradition – we are down-to-earth eastern Westphalians

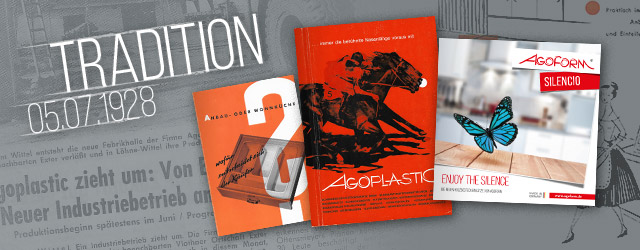

On 5th July 1928 the merchant August Ottensmeyer, born on 2nd April 1905 in Löhne-Bischofshagen , registered his business in Löhne as a travelling salesman. Attending commercial school in the mornings, he spent the afternoons selling curtain fabrics and fittings to his customers in the emerging kitchen furniture industry in the region – after a short while even being able to buy and use an own car. War and capture abruptly interrupted his successful activities which, however, he took up again and extended further as soon as the war was over.

In 1956, as the very first person to do so, August Ottensmeyer developed a thermoformed plastic cutlery insert carrying the brand-name AGOPLASTIC cutlery insert, and built up the production necessary to fabricate it.

In 1968, on completing his studies in business economics, his son, Jürgen Ottensmeyer, took over the management and in 1980 the company, the name of which was changed to AGOFORM GmbH.

1969 saw the laying of the foundation stone for the first building phase at the company’s present location in Gewerbestraße 27. In 1970, the company then moved from Exter to its present headquarters in Löhne.

From 1985, its own extrusion line enabled the company to extend and widen the value-added chain, making it possible for it to accommodate the customer’s wishes with even greater flexibility and individuality. With an own in-house development, the polystyrene-based non-slip mat, a new product established itself on the market.

In mid 2007, on qualifying as a banker and process engineer as well as graduating as an industrial engineer, Jan Ottensmeyer takes over the family business, being the third generation to do so. Since then, together with the graduate engineer Michael Ruprecht, he has formed the management of AGOFORM GmbH. In the following ten years, the company grows steadily from making a turnover of some 22 million euros with 535 customers, to achieving an international turnover of around 30 million euros with customers in more than 60 countries across the globe.

Since 1970, we have been firmly rooted to our headquarters in Löhne’s Gewerbestraße, which in line with the expansion of the business we continually extend and modernise. This is where we feel at home. Our employees, most of whom have been working for the company for decades, are from the region – in fact, some now represent the second generation. Together we feel duty-bound to do justice to the “Made in Germany” quality claim. We produce exclusively in Löhne, at the heart of eastern Westphalia, i.e. in the middle of Germany. We are proud to have been a reliable business partner to many of our customers and suppliers over decades.